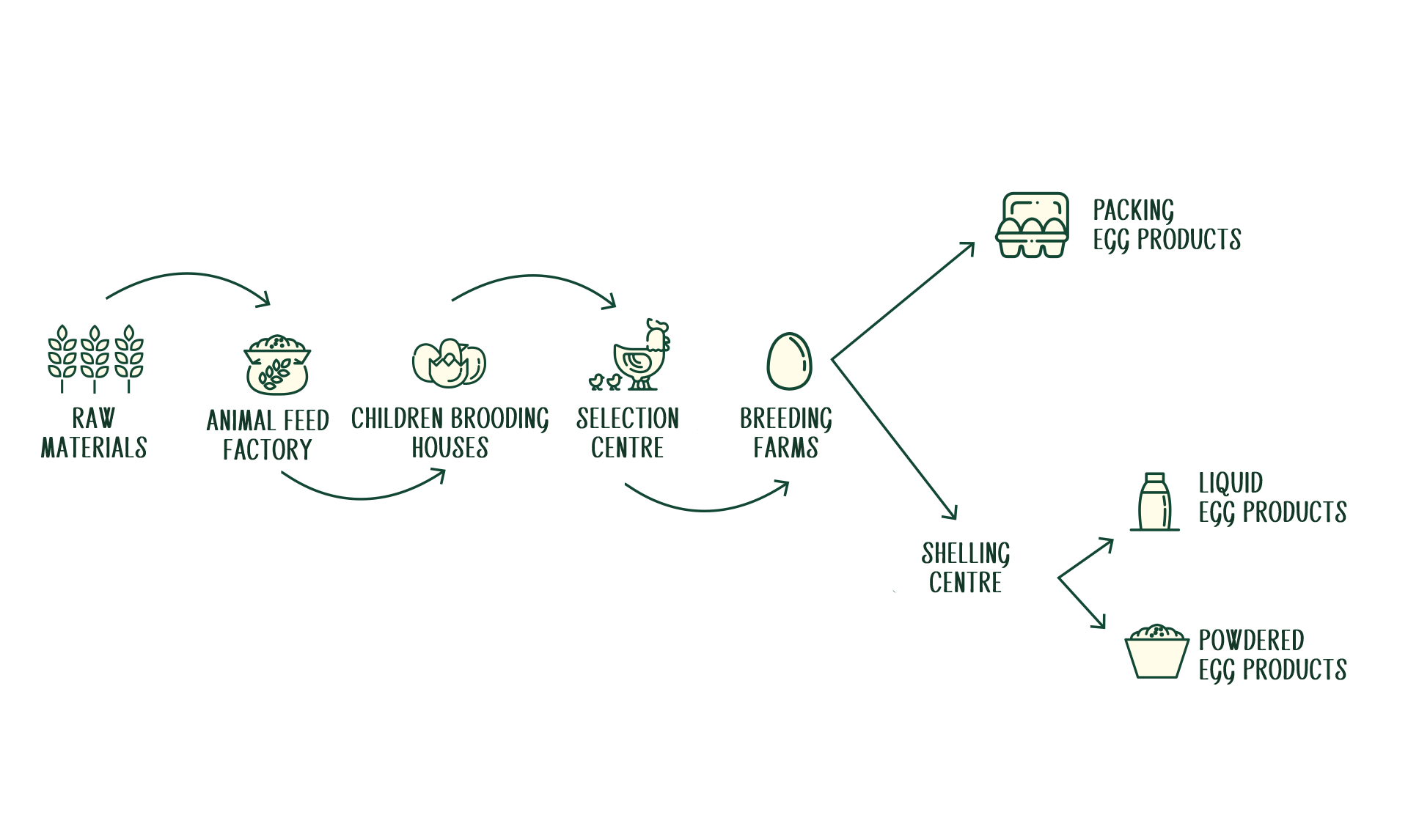

In our own feed factories we formulate balanced and optimised foods according to the different ages of the animals. Our laboratories control the entire production, starting from the selection of raw materials from suppliers subject to regular controls. The same feed is only transported, in order to guarantee the best hygienic and sanitary conditions.